Zhengzhou Dongding Machinery Co., Ltd.

Capacity: 300-2500 T/D

Initial Moisture:≤30%

Final Moisture: ≤8%

Whatsapp: + 86 15736930209

Whatsapp: + 86 15736930209

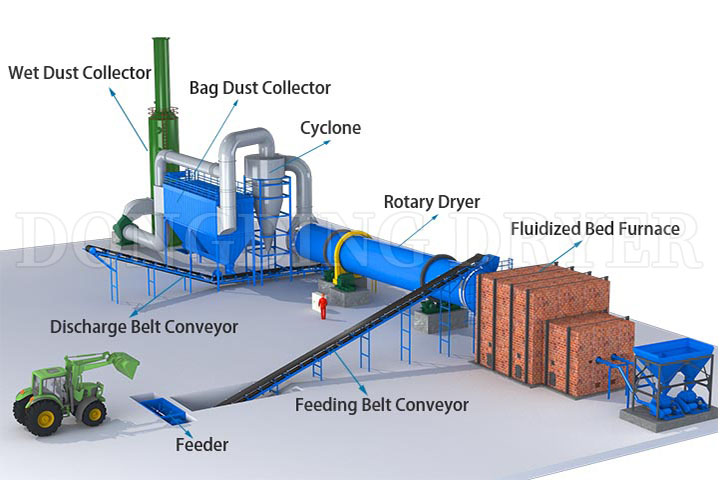

Mineral Rotary Dryer Introduction

Mineral dryers are generally suitable for drying granular and bulk materials, also can be used to dry sticky materials. They are often chosen to dry kinds of mineral for their robust processing capabilities and their ability to produce uniform results despite variance in feedstock. Mineral dryers are widely used in building materials, metallurgy, mineral processing, chemical industry, cement and other industries.

Application & Materials

We can design different internal structures according to the characteristics of the materials; to meet your drying requipments while maximizing thermal efficiency and reducing the cost of drying projects. Our mineral dryer can be used to the drying of following material

Alumina

Barite, Basalt,Bauxite

Chromite, Clay

Ferrous minerals, Fluorite

Graphite, Gypsum

Iron ore

Limestone, Lithium

Phosphorus, Potash, Pumice

Magnesium, Manganese, Molybdenum

Rutile

Sand, Silica, Struvite

Talc

Vermiculite

Mineral Rotary Dryer Running Video

Mineral Rotary Dryer Features

1. High Efficiency:

Rotary dryers are highly efficient in processing large quantities of materials, which can save time and energy.

2. Versatility:

Rotary dryers can be used to process a wide range of minerals, including rocks, ores, and other minerals.

3. Controlled Drying:

The rotary drum design allows for precise control over the drying process, ensuring uniform and consistent results.

4. Reduced Downtime:

The durable and reliable design of rotary dryers results in reduced downtime for maintenance and repairs.

5. Energy-Saving:

Rotary dryers are designed to consume less energy compared to other drying methods, which can result in cost savings.

6. Customizable:

Rotary dryers can be customized to fit specific processing needs, including size, capacity, and temperature requirements.

Mineral Rotary Dryer in Factory

Customer Visit

Mineral Rotary Drum Dryer Cases

Specifications

|

Specification |

Capacity |

Initial Moisture |

Final Moisture |

Total Power |

Floor Area |

| DDMG1918 |

300±10 |

25±5 |

≤8 |

109 |

7*25 |

|

DDMG2218 |

500±30 |

25±5 |

≤8 |

128 |

8*30 |

|

DDMG2520 |

700±30 |

25±5 |

≤8 |

240 |

8*30 |

|

DDMG2822 |

1000±30 |

25±5 |

≤8 |

400 |

8*40 |

|

DDMG3024 |

1200±30 |

25±5 |

≤8 |

480 |

12*50 |

|

DDMG3428 |

1500±30 |

25±5 |

≤8 |

600 |

12*60 |

|

DDMG3830 |

1800±30 |

25±5 |

≤8 |

800 |

16*70 |

|

DDMG4032 |

2000±30 |

25±5 |

≤8 |

1000 |

18*70 |

|

DDMG4238 |

2500±30 |

25±5 |

≤8 |

1200 |

20*80 |

Send Inquiry